Material Solutions for

EV Motors & Battery Systems

Material Solutions for

EV Motors & Battery Systems

Request a quote or more information

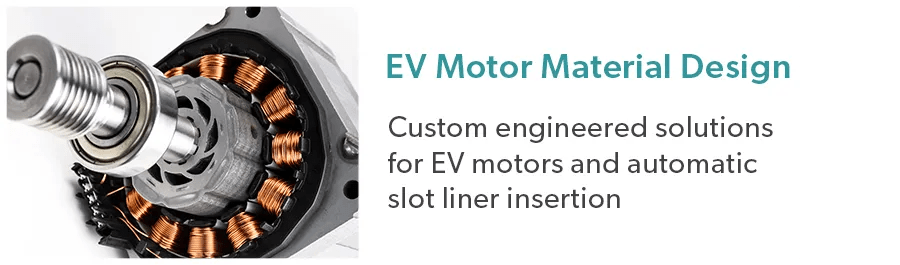

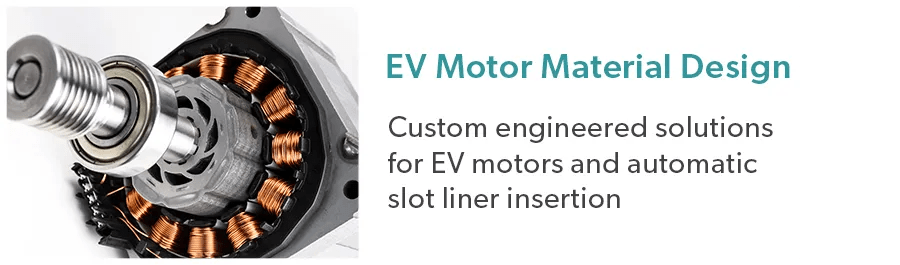

EIS addresses critical laminate issues and mitigates automatic insertion challenges for slot liners in EV motor production.

Delamination in slot liner insulation leads to decreased performance, engine waste heat, and even severe motor failure.

EIS has overcome this challenge by using a single substrate insulation liner instead of laminated material, ensuring slot liners do not jam or get damaged during the automatic insertion process into EV motors.

Leveraging our advanced materials and converting capabilities, we provide slot liners and many more custom fabricated and distributed products used in manufacturing EV motors, leveraging advanced materials and converting capabilities.

EIS is North America's leading supplier of electrical, electronic, and mechanical process materials with local stock, bringing together top-tier distribution products and cutting edge fabrication and converting capabilities.

EIS is North America's leading supplier of electrical, electronic, and mechanical process materials with local stock, bringing together top-tier distribution products and cutting edge fabrication and converting capabilities.

Electric Vehicle Motor & Battery Materials

Lacing Cord →

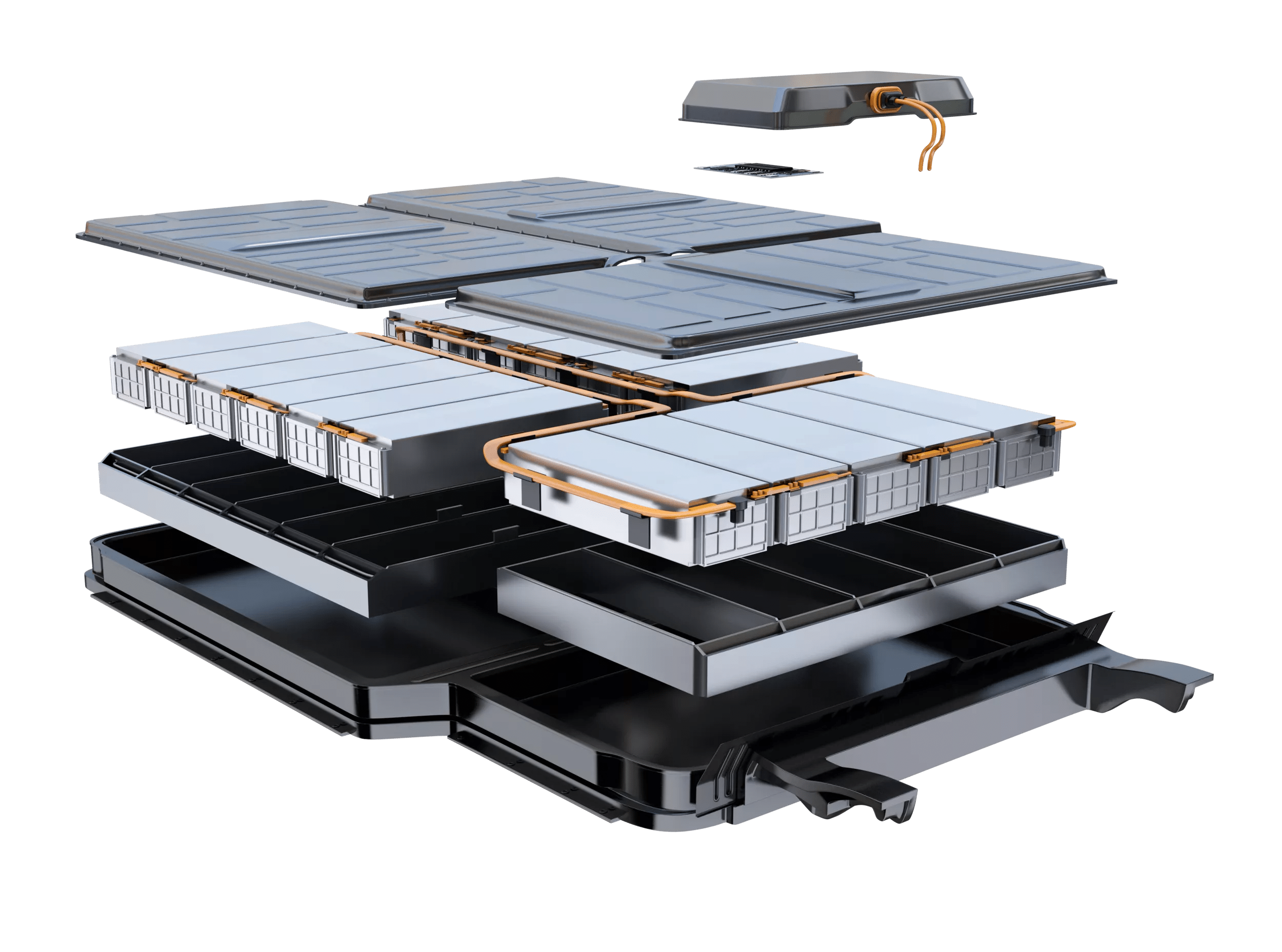

EV Battery Systems

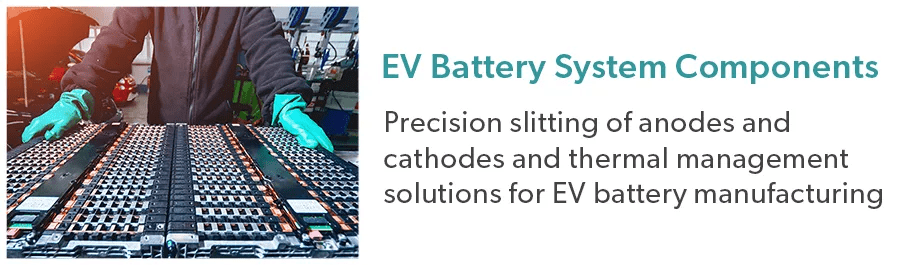

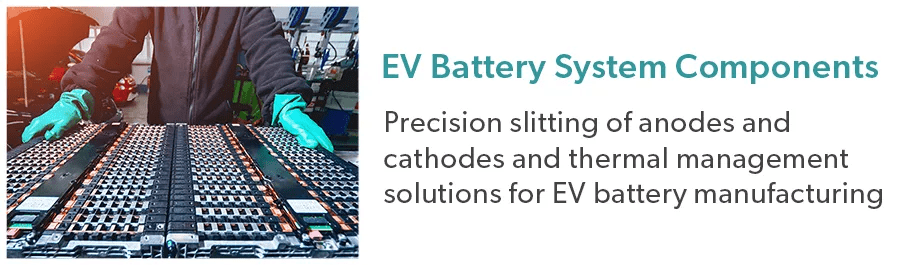

The complexity and power of batteries used in EVs require the manufacturer to work with knowledgeable materials expert for electrical insulation, electrical connection, heat dissipation, or packaging and protection.

EIS offers advanced thermal management solutions, including thermal insulation/dissipation and sealant materials to provide thermal runaway protection and fire resistance in and between battery packs. Our solutions ensure proper heat dispersion and effective fires containment, enhancing safety and reliability.

Moreover, poor edge control in the slitting of aluminum and copper-based anodes and cathodes leads to decreased performance, inefficient charging, and even severe motor failure. With EIS' precision slitting and rapid prototyping, you'll reduce production costs and increase battery longevity, with materials converted to your exact specifications.

Our engineered solutions provide OEM manufacturers and aftermarket customers with a highly technical, integral partner in development serving industries from electrical power and electronic assembly to alternative energy and EV mobility.

Automotive Fabrication & Labeling

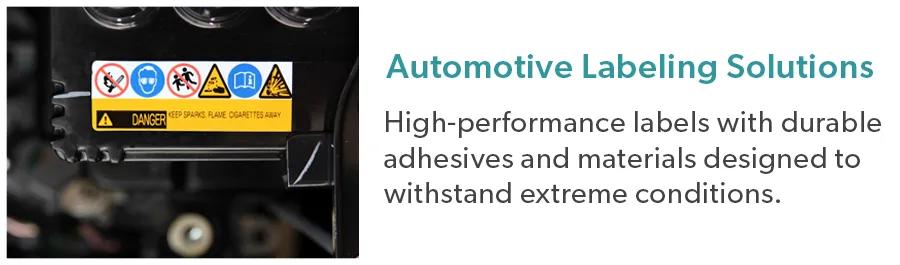

The demanding conditions of electric vehicles require durable, high-performance labeling solutions to ensure safety, compliance, and long-term reliability. EIS provides advanced automotive labels engineered with high-strength acrylic adhesives and specialty face stock materials, offering superior adhesion to low-energy plastics and coated metals. Resistant to extreme temperatures, chemicals, and moisture, our labels maintain clarity and durability in both interior and exterior applications.

EV Motor Material Design

- Performance slot liner insulation – avoid delamination and auto insertion issues.

- Prime material sourcing and optimal lead times.

EV Battery System Components

- Precision slitting and edge control for anodes and cathodes

- Rapid prototyping and thermal management solutions – fire resistance and thermal runaway

Automotive Labeling Solutions

- High-performance automotive labels with durable adhesives and materials designed to withstand extreme conditions.

- Certified labeling solutions ensuring compliance, safety, and traceability for VINs, warnings, and identification in both interior and exterior applications.

EV Motor Material Design

- Peak performance slot liner insulation – avoid delamination and auto insertion issues.

- Prime material sourcing and optimal lead times.

EV Battery System Components

- Precision slitting and edge control for anodes and cathodes

- Rapid prototyping and thermal management solutions – fire resistance and thermal runaway

Automotive Labeling Solutions

- High-performance automotive labels with durable adhesives and materials designed to withstand extreme conditions.

- Certified labeling solutions ensuring compliance, safety, and traceability for VINs, warnings, and identification in both interior and exterior applications.

EIS is a leader in supplying materials for the Electric Vehicle market and continues to make strides with innovative technology and strategic supply solutions.

Give your company a head start in the current innovations and technology by working with a company with a legacy of supplying products to electric motor and electronic manufacturers.